Description

The Semi-Automatic Capsule Filling Machine by H.L. Scientific Industries is designed to efficiently fill hard gelatin or vegetarian capsules with powders, granules, or pellets. It’s particularly suitable for small to medium-scale production in pharmaceutical, nutraceutical, herbal, and cosmetic industries.

🔧 Key Features

-

Production Capacity: Depending on the model, the machine can fill up to 45,000 capsules per hour.

-

Compatibility: Supports capsule sizes ranging from 00 to 5.

-

Construction: Built with stainless steel (SS 316) contact parts and a magnesium alloy loading ring, ensuring durability and compliance with Good Manufacturing Practices (GMP).

-

Filling Mechanism: Equipped with a four-speed auger system, allowing precise filling of various materials.

-

Automation: Features include automatic declutching of the loader after one complete rotation, PLC-controlled digital display, and pneumatic capsule closing, enhancing efficiency and reducing operator fatigue.

-

Ease of Maintenance: Modular design allows for quick dismantling and cleaning, facilitating easy changeover between batches.

📐 Technical Specifications

| Model | LSCF-35 | LSCF-45 |

|---|---|---|

| Output/hr | Up to 35,000 caps | Up to 45,000 caps |

| Loading Ring | Single | Double |

| Holes/Ring | Size 00: 480<br>Size 0: 600<br>Sizes 1–5: 720 | Same as LSCF-35 |

| Power Supply | 3 Phase, 415V, 50Hz | 3 Phase, 415V, 50Hz |

| Compressed Air | 8 CFM | 8 CFM |

| Dimensions (L×W×H mm) | 1950×1200×1800 | 2650×1250×1800 |

| Net Weight | 1100 kg | 1250 kg |

🛠️ Operating Procedure

-

Capsule Loading: Empty capsules are fed into the hopper.

-

Separation: The machine separates capsule caps from bodies.

-

Filling: Capsule bodies are filled with the desired material using the auger system.

-

Closing: Filled capsules are rejoined with their caps and sealed.

-

Ejection: Sealed capsules are ejected and collected for further processing.

✅ Benefits

-

High Efficiency: Significantly increases production speed compared to manual methods.

-

Cost-Effective: Lower initial investment and maintenance costs than fully automatic machines.

-

Flexibility: Easily adaptable to different capsule sizes and materials.

-

User-Friendly: Simple operation requiring minimal training.

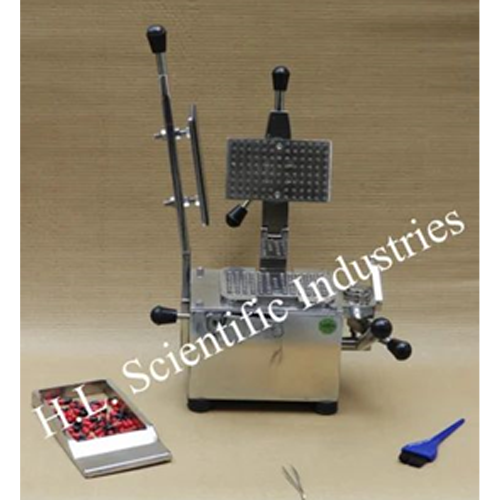

Capsule Filling Machine is a versatile lever operated semi automatic machine for various operations with lever order of:

1. Plates for putting of capsules by hand.

2. Removal of Caps.

3. Filling of powder by dispensing of brush pressing.

4. Fixing of caps and selling.

5. Injection of capsules contact parts of stainless for 100 capsules of size 0.

6. Capacity of 200 Capsules on order.

Any other size as per your requirement.